Please enter your information here to receive updates

Click Hereabout

A lab is where unique ideas are generated and early prototypes are synthesized. A factory is where designs are mass produced and quality is validated. They seem so far away from each other, that we usually separate research from reality, prototype from production. How can we demolish this separation for a future where design, technology and production are tightly coupled together? The overall goal of our Hacking Manufacturing month was to explore how to do academic research on the factory floor. Specifically, we wanted to see new outcomes from using manufacturing machines to prototype, rather than traditional prototyping tools. Usually when people go to a factory, they want to produce something that has been well-planned and has clear economic value. Instead, we wanted to bring the spirit of a lab to the factory: What if we could collaborate with its workers, directly prototyping and trying out ideas on the very machines that are used for production? What if curiosity were our only pressure point? Benefits would flow—not only from new academic research for publication but also from bringing prototyping closer to production in the ideation phase. By definition, the prototypes would be production-ready.

Event

HM Workshop 2018

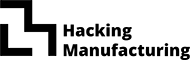

Leather Factory

by Artem Dementyev PrimeAsia leather tannery in Dongguan. The tour was given by Sergio, one of the managers at the plant. Big thanks to Sergio for the tour. This factory converts cowhides into different types of leather. As many tanneries in South China, it...

Read More

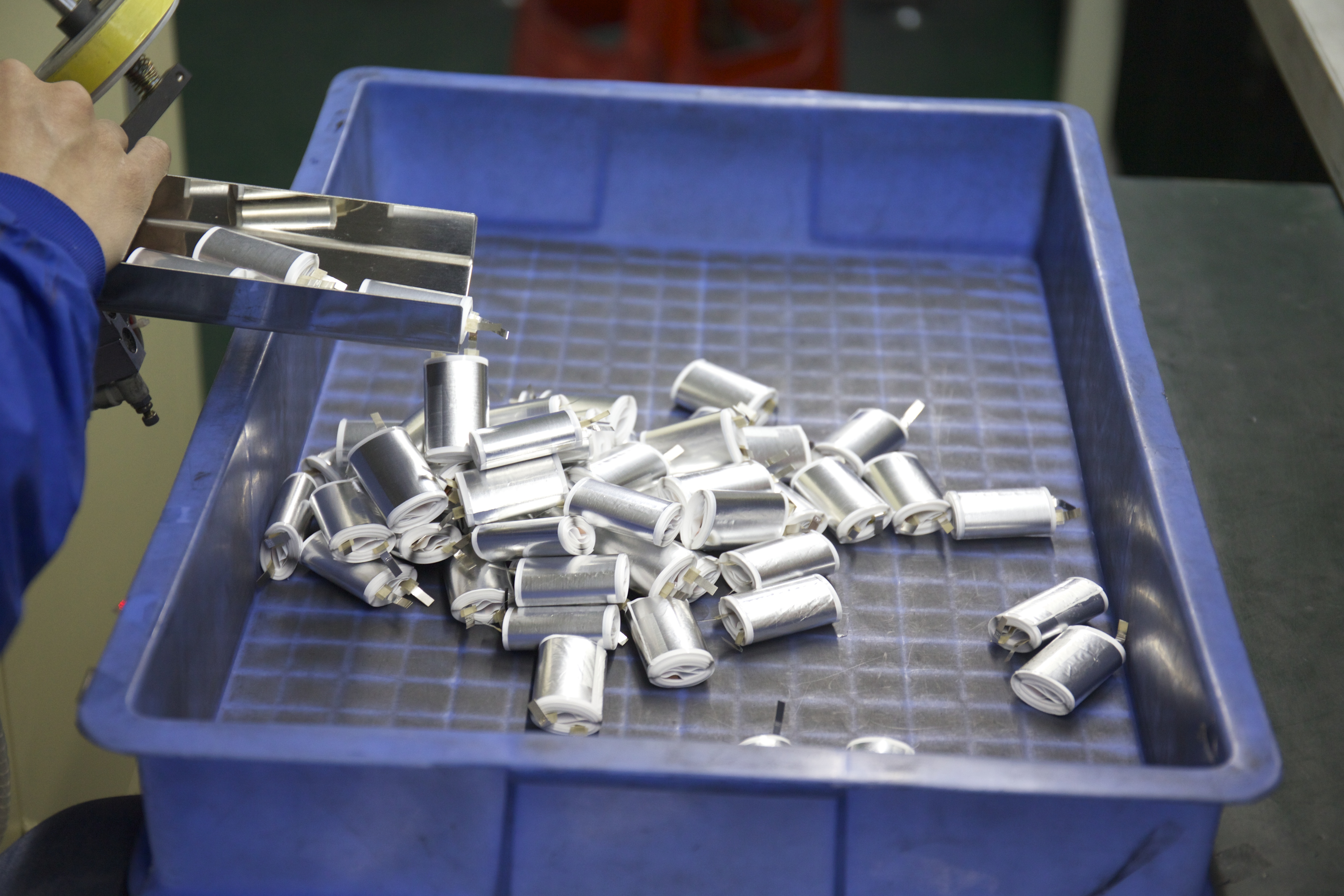

Battery Factory

By Artem Dementyev and Cindy Kao We visited two lithium-polymer (LiPo) battery manufacturers around Shenzhen: Full River and Shenzhen Sunbang-Power Technology Co., Ltd. LiPo batteries are commonly used in consumer electronics such as cell phones. One of ...

Read More