By Artem Dementyev and Cindy Kao

We visited a rigid PCB manufacturer, Kings Creddie. The rigid PCB technology involves sophisticated machines and chemical processing. But the technology is very well established, and is already well documented.

Raw copper sheet on which traces are added later.

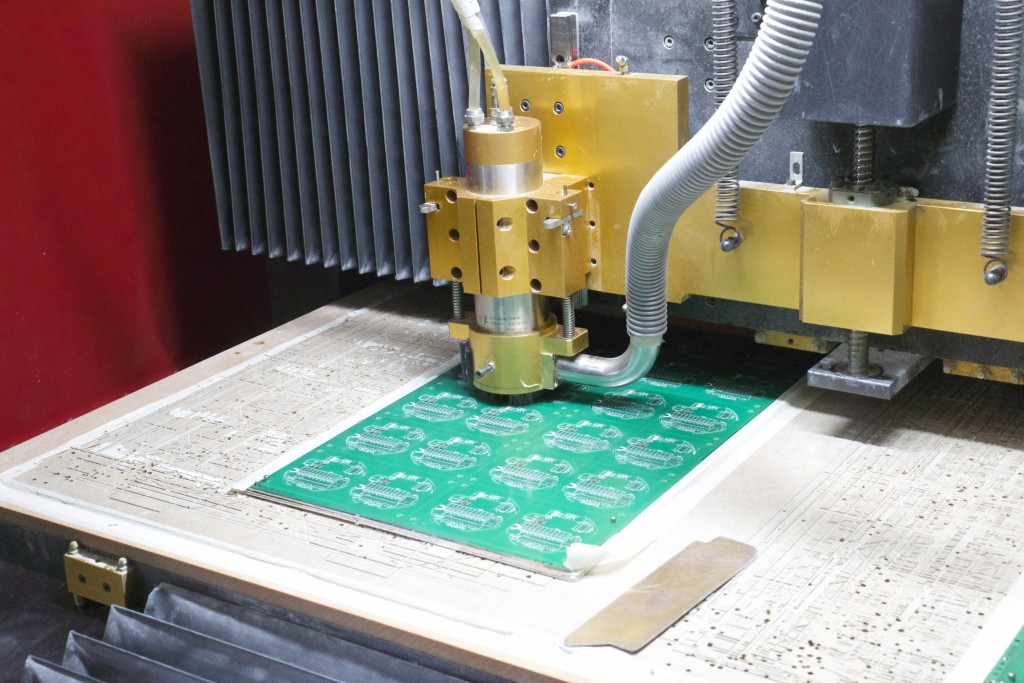

The holes on the copper board are drilled with those large CNC drills.

The individual boards are cut from a larger panel by this machine.

Cleanroom, where the UV etching is done.

Electroplating is used to connect the vias from one side to the other

Machine that automatically tests electrical connections.